As new technologies and innovations emerge in the microtunnelling industry, contractors’ capabilities to meet some of the industry’s toughest challenges continue to grow. For example, very hard rock used to result in most contractors turning down projects or stopping a job part way through when they unexpectedly hit these conditions. This is because most microtunnelling tools struggle to drill through very hard rock and install a pipeline to specifications, but new cutting-edge trenchless equipment can now do so with high precision. This is only one example, there are a number of new technologies that are helping to pave the way for the future of microtunnelling.

Air hammer drilling tool

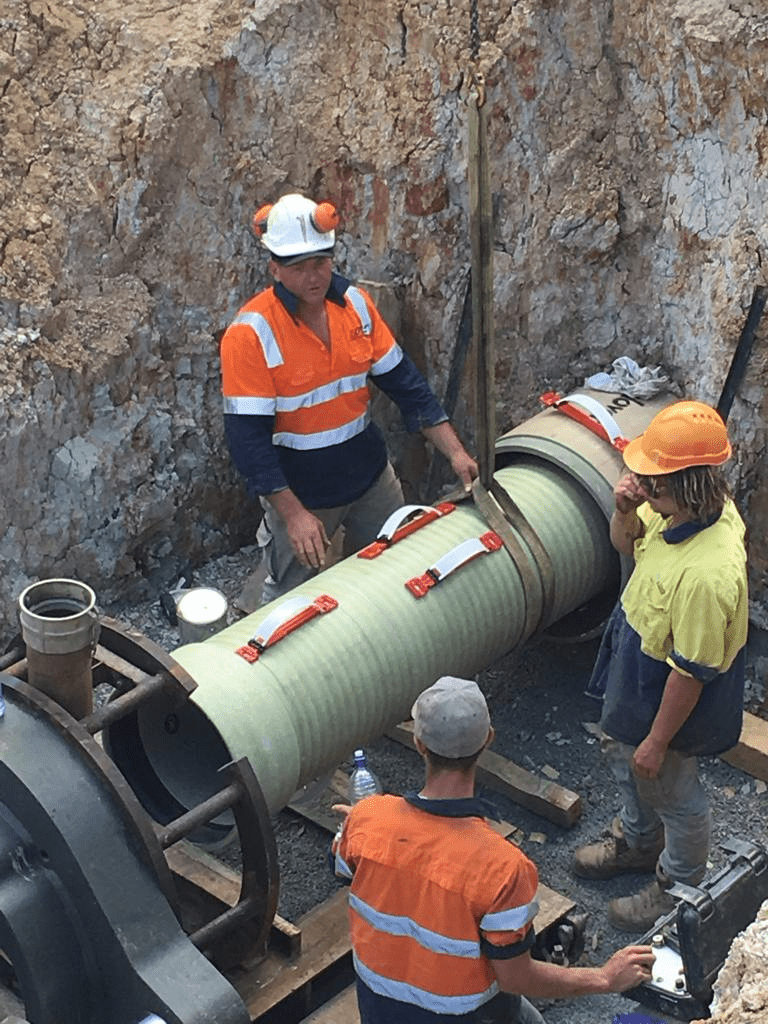

The air hammer is a new technology, ideal for use in high strength rock as it allows contractors to take on jobs that they would previously have avoided. The new technology is based on a new pneumatic rock hammer – which uses air driven hammers (similar to vertical DTH heads), with a pilot line guiding the head to maintain accuracy.

The air hammer was developed to meet the increasing need for drilling rock on fine grades and a lack of options available to do so with high rates of success and/or time and cost efficiency. It also provides environmental and workplace health and safety benefits, by enabling small to medium size pipe diameters to be installed in hard rock faster, with a significant reduction in spoil removal and truck movements compared to open cut methods.

This equipment can handle a variety of tricky conditions, and install pipelines of various diameters (100 to 3,000mm), whilst maintaining accuracy, productivity and efficiency while also providing environmental and health safety benefits.

It can be operated via the next generation AXIS drill rods with a power enhancing driver, and has been tested and proven with the extra heavy rods of the AdaptX – a new machine on the market with unparalleled capabilities, manufactured by Bournedrill.

Riteline

A new spacer innovation that is purpose-built to improve the accuracy of trenchless pipeline installations, Riteline casing spacers assist the carrier pipe during installation by maintaining its position relative to the bored hole or encasement pipe. The spacer’s design means its height can be adjusted from 30mm up to 125mm, allowing multiple configurations from the one unit.

Riteline’s adjustable design means contractors who use them don’t need to have multiple products on hand – they can be installed to suit the project’s needs, even if requirements change at the last minute.

Unlike other spacers on the market, they are also spring-loaded, which means you can adjust the tension as required, and they flex when they hit rock – so they won’t break. This also removes the issue of them floating when grouting takes place.

AdaptX

Most drilling machines are only capable of utilising one or two drilling techniques. However, there is a new drilling machine on the market that boasts capabilities that are unmatched across the globe. AdaptX is a modular drilling platform that allows the contractor to use most drilling techniques all in the one machine, including: vacuum, pressure air vacuum, slurry, HDD, displacement pilot, auger boring, bed boring, box culvert jacking and canopy tunnel drilling.

This gives contractors more options for different methods all in the one machine, allowing them to not only take on more jobs but be flexible on the job site if unexpected circumstances occur to ensure the best method for the job is used.

Scope for more innovation

These exciting new tools are unlocking many new opportunities for contractors and there is still a lot of scope for evolution in the microtunnelling industry. As more companies find new ways to get the job done and equipment capabilities continue to expand with new technology, confidence in trenchless installation will build and more contractors will be able to take on more jobs.