Boring on grade

When Melbourne’s Eastlink tollway began experiencing underground water pooling, Edge Underground devised an innovative boring on grade solution to a challenging problem. The Thiess/John Holland joint venture called the team at Edge Underground in when regular maintenance works on Eastlink revealed underground water pooling – leading to concerns about the potential for water to rise up to the road. After investigating the situation, the Edge Underground team suggested that two microtunnelling bores should be completed, which would trap the pooling water and give it an easy path to the nearby drainage system. By putting a screening in at a depth...

Read More

How has the Vermeer AXIS guided boring system developed over the years?

When first launched in 2009, the Vermeer AXIS guided boring system was intended for use with pipe up to 300mm in diameter. Since then the product has continually evolved, and AXIS now regularly installs pipe in the 300-600mm range, and to date, the largest ever installation was of a 900mm pipeline. When AXIS initially launched, a lot of people though it would only be suitable for use in self-supporting ground. However over the course of the last five years, it has repeatedly been proven that AXIS can be used in all variety of ground conditions, including below the water table....

Read More

Completing a successful microtunnel: tips for head contractors and project owners

Precision microtunnelling works can be demanding, and often a number of challenges must be met in the course of a project. More often than not, unexpected challenges relate to the prevailing ground conditions. In order for the project to be successful, the microtunnelling contractor involved must have the necessary capabilities to deal with the requirements of the work and the job site. The most important thing to consider before undertaking any precision microtunnelling project is the prevailing ground conditions at the project site. The more the project owner, contractor and subcontractor know about the ground conditions, the less likely that...

Read More

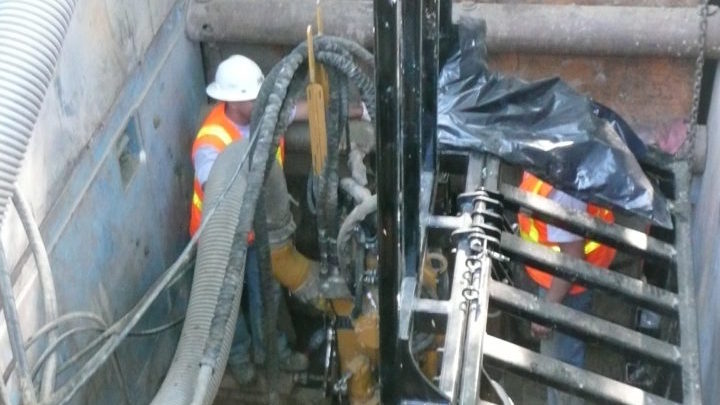

What is the AXIS guided boring system?

The Vermeer AXIS guided boring system is a pit-launched trenchless installation method designed to achieve pinpoint, on-grade accuracy while eliminating some of the difficult steps associated with other installation techniques. A wide range of product pipe, sizing specifications, and other jobsite requirements can be met with the versatile capabilities of the AXIS system. The system gives on-grade accuracy and high efficiency, while minimizing restoration and installation costs. These characteristics have seen the AXIS system used on many a jobsite around the world in the past five years, and the system has developed a reputation for getting the job done, every...

Read More

Best practice for microtunnelling subcontractors

Microtunnelling projects are frequently complicated. No matter how much you, or the project owner, think you know about a job site, there is always a chance of running into unexpected ground conditions or foreign objects may lie hidden underground. A microtunnelling subcontractor must be prepared to deal with unforeseen circumstances and have a backup plan if things go wrong. Quitting when things get tough is not an option for anyone who intends to remain in this field for long. Thankfully, there are a number of steps that microtunnelling subcontractors can take to ensure that, regardless of unforeseen circumstances, they go...

Read More

What are the most important factors to consider before commencing any microtunnelling job?

Before you begin any microtunnelling job, there are several critical factors to consider, according to microtunnelling expert and Vermeer AXIS inventor Stuart Harrison. Understanding the prevailing ground conditions is paramount in getting successful outcomes from microtunnelling. Your findings in regard to the prevailing ground conditions will then also go a long way to determining the type of pipe to be installed, and the length of the line. The equipment to be utilised will also be somewhat determined by the geotechnical information provided. Because the ground conditions are such a critical aspect of any microtunnelling job, before appointing a microtunnelling contractor,...

Read More

Key-hole pipelining to Melbourne’s heart

As part of the regeneration of Melbourne’s Victoria Harbour, one of the most prestigious waterfront developments being undertaken in Australia, microtunnelling contractors Edge Underground has performed minimally invasive key-hole pipelining to install a new gravity sewer. Project Overview Excavation contractor: Jayelle Pipelines Microtunnelling contractor: Edge Underground Pipe supplier: HOBAS, OD427 mm pipe Melbourne’s Victoria Harbour is receiving a new, integrated precinct that includes housing and commercial buildings. The partnership owners of the project will be delivering ‘Dock Square’ – a new civic hub and community centre. With the development of new high-rise buildings and apartments comes the need for new associated water and...

Read More