Microtunnelling – Pipe Jacking – Thrust Boring – Laser Tunnel Boring

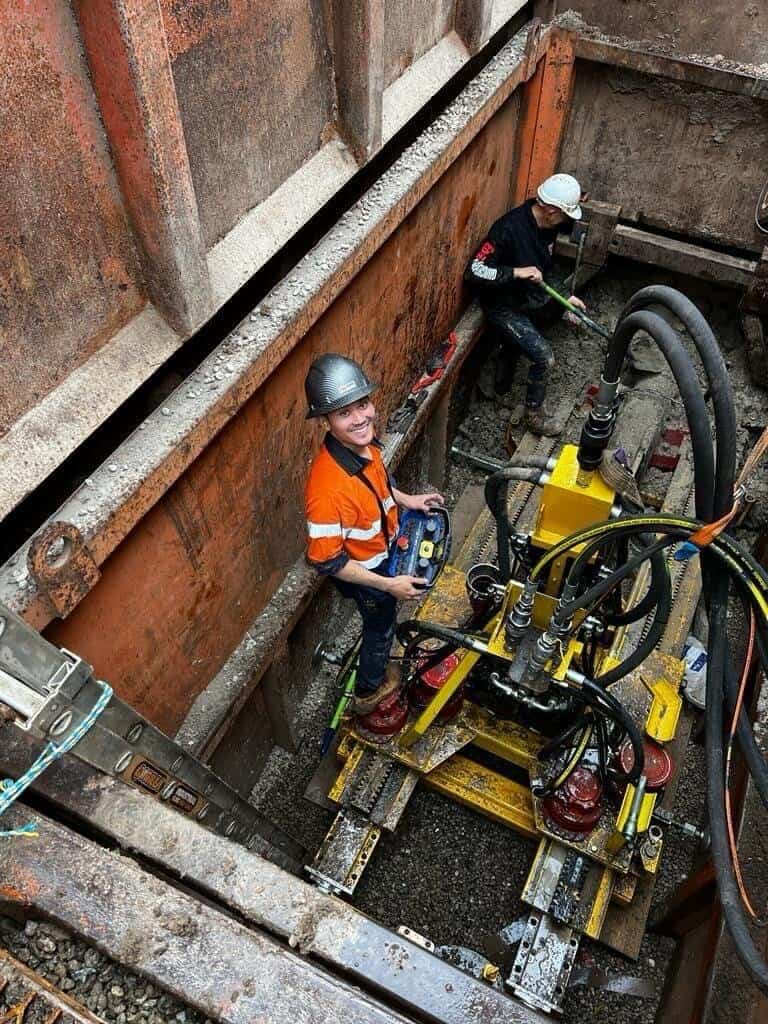

Edge Underground delivers precision trenchless pipeline installations across Australia, specialising in vacuum microtunnelling for gravity sewer, stormwater and water projects.

As part of the OptionX Group, we operate with Australian-designed and manufactured technology, ensuring every project is completed with accuracy, efficiency and innovation.

ABSOLUTE PRECISION MICROTUNNELLING

Our core capability is vacuum microtunnelling; a cleaner, faster and more environmentally responsible method for installing gravity pipelines. Our methods are superior to not only other trenchless methods, but our advanced machinery also means we can competitively take on traditionally open-trench pipe installations.

Using AdaptX technology, designed and built in Australia by OptionX Group, Edge Underground achieves ±5–10 mm accuracy in all ground conditions, including rock, mixed ground and water-charged environments.

Key benefits of vacuum microtunnelling:

- Continuous, clean operation with no slurry or auger handling.

- Reduced site footprint and setup time.

- Safe, non-man-entry system.

- Lower operating and reinstatement costs.

- Proven reliability in challenging conditions.

ANY GROUND, ANY CHALLENGE

Edge Underground has the expertise and equipment to complete trenchless installations through all ground types, including:

- Consolidated and mixed ground

- Clay and shale

- Sand and silt

- Hard rock (basalt, granite, limestone)

- Fractured or water-charged conditions

Our systems are engineered to maintain grade accuracy even in complex transitions, ensuring structural integrity and consistent flow.

Pipeline Sizes and Materials

We specialise in small- to medium-diameter installations, ranging from 350 mm to 1,800 mm and beyond. Each project is planned to match pipe type, ground conditions, and line length for maximum efficiency and lifespan.

Pipe materials include:

- Steel casing

- Ductile iron

- HDPE

- HOBAS

- PVC locked

- Clay pipe

Design and Construct (D&C) Delivery

Edge Underground provides a full Design and Construct (D&C) service — from feasibility studies and engineering design to microtunnelling delivery and final QA documentation.

Our approach ensures seamless collaboration with contractors, consultants, and authorities while maintaining strict compliance with required standards.

Features include:

- Live monitoring and telemetry data.

- Digital bore logs and QA reporting.

- Custom-engineered casing and platform systems through OptionX Bournedrill.

- Integrated safety and environmental management.

PART OF THE OPTIONX GROUP

Edge Underground operates within OptionX Group, an Australian-owned network of companies pioneering trenchless innovation:

- OptionX Bournedrill – manufacturing and engineering excellence.

- Riteline – advanced casing spacers and centralisers.

- AdaptX – Advanced microtunnelling machines.

- PerforatorX – German engineered, Australian-made drill rods

- Drillit International – equipment ownership and leasing.

This vertical integration ensures rapid innovation, unmatched equipment support and Australian-made reliability.

WHY CHOOSE EDGE UNDERGROUND

- World-leading vacuum microtunnelling technology

- Proven performance in complex and high-risk ground conditions

- Australian-owned, Australian-made, globally recognised

- End-to-end D&C solutions with real-time data capture

- Reduced risk, waste, and cost across every project