How new versatile equipment is reducing risks to project delivery in microtunnelling

Microtunnelling projects often encounter a variety of complex challenges that can prove costly and push out project delivery timelines. However, contractors with versatile equipment can easily adjust to unexpected issues – by changing drilling heads, and being able to install a wide range of pipe materials and diameters – to ensure a project is delivered on time and on budget. When working with versatile equipment, contractors are able to adapt and adjust their approach whilst using their knowledge around the existing ground conditions and their equipment, to dramatically reduce risk in a microtunnelling project. Versatility is especially important given the...

Read More

Never resting on laurels: striving to expand trenchless capabilities, even after major successes

With the help of innovative technology such as the AXIS, Edge Underground has installed hundreds of thousands of meters of sewer and water pipelines under various ground conditions - from easy to challenging. However, despite these successes, Edge Underground is always looking for ways to increase capabilities and reduce risks to project delivery. Maribyrnong development sewer When the builders of a new 20-storey development, located beside a busy tram stop in Maribyrnong, needed to install a sewer for the building, they found it difficult to find contractors who would take the job. The development was in the middle of a...

Read More

What are some of the new innovations increasing capabilities in the microtunnelling industry?

As new technologies and innovations emerge in the microtunnelling industry, contractors’ capabilities to meet some of the industry’s toughest challenges continue to grow. For example, very hard rock used to result in most contractors turning down projects or stopping a job part way through when they unexpectedly hit these conditions. This is because most microtunnelling tools struggle to drill through very hard rock and install a pipeline to specifications, but new cutting-edge trenchless equipment can now do so with high precision. This is only one example, there are a number of new technologies that are helping to pave the way...

Read More

Expertise and innovation: increasing the capabilities of microtunnelling machines

In order to make the microtunnelling industry more competitive and able to take on even more jobs, the committed team from Edge Underground – part of OptionX Group – uses its expertise and drive to set a benchmark in the industry, pushing the limitations of current equipment capabilities by modifying and designing new equipment that is more capable. This culture of innovation has led to the development of the air hammer, a drilling tool that addresses the challenges of drilling in very hard rock, providing microtunnelling contractors a solution that increases rates of successful pipeline installation, while still maintaining accuracy,...

Read More

What are the benefits of utilising an air hammer drilling tool in microtunnelling?

In the past, very hard rock has posed a problem for microtunnelling machines, with most tooling struggling to successfully drill through it to install a pipeline to specifications. This means most contractors turn down projects where the geotechnical information has identified this ground condition or stop a job part way through when they unexpectedly hit very hard ground. A new drilling tool – an air hammer – has been designed and proven to work in very hard rock while maintaining accuracy, productivity and efficiency, and providing additional environmental and work health and safety benefits. Drilling through rock The new technology...

Read More

Microtunnelling through basalt and very hard rock

Installing pipelines via trenchless methods such as microtunnelling in areas where there has been volcanic activity presents a number of challenges. Depending on the conditions, and pipeline route and specifications, there could be few options available and may result in higher costs for the client. However, a new, innovative advancement by Edge Underground is allowing for easier drilling in difficult hard rock conditions. Stuart Harrison, Managing Director at Edge Underground, said that there are a number of conditions that can be found in areas where volcanic activity has taken place, including intersecting lava flows, quenching, lava tunnels and extreme rock...

Read More

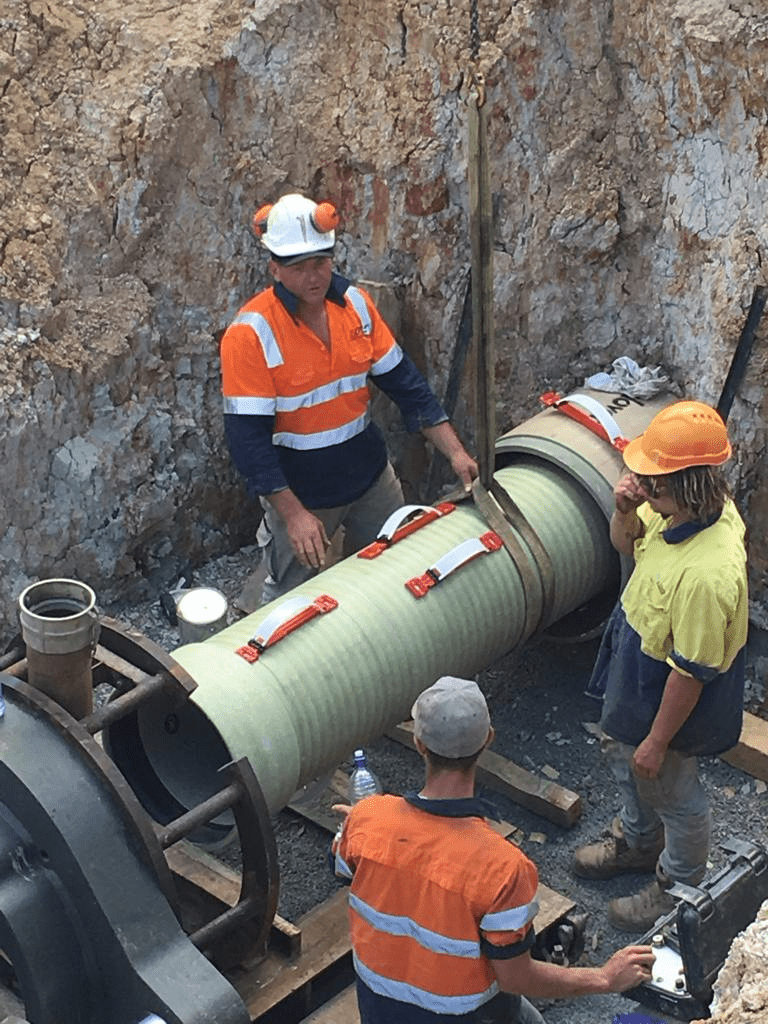

Drilling in reinstated goldfields: communication for optimal outcome

Areas that were previously goldfields pose a challenge for trenchless pipeline installations due to the unpredictability of the ground conditions and the high likelihood of hitting reinstated ground. In this situation, communication between the principal contractor and subcontractor is vital as the best course of action can change at any moment, potentially influencing the timeline, costs and outcome for the project. This scenario played out in a project in Ballarat, where Edge Underground needed to suggest alternative options to account for the ground conditions. In areas around Australia that have a gold rush history, such as Ballarat and Bendigo, the...

Read More